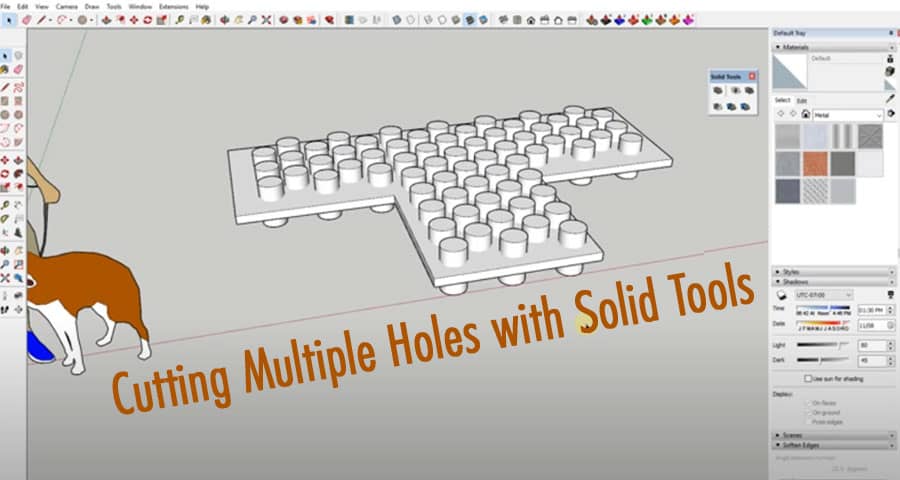

Solid tools are commonly used in machining processes for creating complex shapes and holes. However, cutting multiple holes with solid tools can be challenging due to several factors, such as tool wear, heat generation, and chip removal.

Understanding the Challenges of Cutting Multiple Holes

Before diving into the techniques, it is essential to understand the challenges involved in cutting multiple holes with solid tools. Some of the primary challenges include:

Tool Wear

Solid tools can wear out quickly due to the high cutting forces involved in machining. When cutting multiple holes, the tool must go through several cycles of cutting, which can lead to rapid tool wear.

Heat Generation

Cutting generates a lot of heat, which can cause thermal expansion and deformation of the tool. In the case of multiple hole cutting, the tool must dissipate heat effectively to maintain its integrity.

Chip Removal

When cutting multiple holes, chips can accumulate inside the hole, leading to poor surface finish, tool breakage, and other issues. Proper chip removal techniques are critical for successful hole cutting.

Techniques for Cutting Multiple Holes with Solid Tools

Now that we have an understanding of the challenges involved in cutting multiple holes, let’s discuss the techniques used for this process:

Peck Drilling

Peck drilling involves drilling a hole in several small steps, each one slightly deeper than the previous. This technique allows for better chip removal and reduces the amount of heat generated during the drilling process.

Trepanning

Trepanning involves creating a large hole by removing a ring of material from the workpiece. This technique is suitable for cutting multiple holes with the same diameter, and it can produce accurate and consistent results.

Gun Drilling

Gun drilling involves drilling a long, deep hole in a workpiece. This technique is useful for cutting multiple holes with high precision, and it can produce a good surface finish.

Boring

Boring involves enlarging an existing hole to a larger diameter. This technique is useful for creating multiple holes with different diameters, and it can produce a good surface finish.

Best Practices for Cutting Multiple Holes with Solid Tools

In addition to the techniques mentioned above, some best practices can help achieve better results when cutting multiple holes with solid tools:

Use the Right Cutting Parameters

Choosing the right cutting parameters, such as cutting speed, feed rate, and depth of cut, is essential for successful hole cutting. The cutting parameters should be optimized based on the material being cut, the tool geometry, and other factors.

Select the Right Tool

Choosing the right tool for the job is critical for achieving good results. The tool should be made of high-quality materials and have the right geometry and coatings for the specific application.

Use Proper Coolant and Lubrication

Proper coolant and lubrication can help reduce heat generation and tool wear during the cutting process. The coolant should be selected based on the material being cut and the tool geometry.

Maintain the Tool

Regular maintenance of the tool, such as sharpening or replacing dull or worn-out tools, can help improve the tool’s performance and prolong its lifespan.

Conclusion

Cutting multiple holes with solid tools can be a challenging task, but by understanding the challenges and using the right techniques and best practices, it is possible to achieve accurate and consistent results. Peck drilling, trepanning, gun drilling, and boring are some of the techniques used for multiple holes cutting, and choosing the right cutting parameters, tool, coolant, and lubrication can help ensure successful hole cutting.